My father was diagnosed with Alzheimer’s two years ago. He is now in a Southport EMI care home and has settled in well. He still knows me and I visit often when I’m here. Even though we are keeping his flat, I thought it was time I cleared out some of the stuff he’d been hoarding for ever.

In amongst the bedding I came across some old sheets that I remembered having on my bed as I child.

They were threadbare in the middles and a bit yellowed in places but the edges were still pretty good. So I decided to make a summer memory quilt that will remind me of my childhood every time I come to Southport.

They were threadbare in the middles and a bit yellowed in places but the edges were still pretty good. So I decided to make a summer memory quilt that will remind me of my childhood every time I come to Southport.

First I needed a sewing machine as mine was back in Southampton.

I thought something elderly was quite fitting for the fifty-year old fabrics I was using.

So here’s how I did it.

Instructions

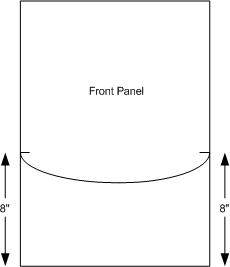

The quilt measures 70″ x 76″, which fits a standard 4’6″ double with a 10″ overhang on the sides and bottom.

For this I needed 90 x 8 1/2″ squares made up of

- 45 x green stripe

- 23 x sprigged fabric

- 23 rose-print (fussy cut so I had a rose in each square)

You will also need 4 metres of cotton batting or curtain interlining (much cheaper!) and a white sheet for the backing.

- Join the squares in rows of nine alternating the green stripe with the floral as shown in the photograph. Ensure four of the rows rows finish with a floral square at each end and the remaining five have a green stripe square at each end.

- Lay your rows out in quilt formation until you are happy with the arrangement.

- Press all the seam allowances of row 1 to the left, those of row 2 to the right, row 3 to the left and so on until all rows are pressed.

- Join all the rows together, slotting the seams together at the little step (produced by pressing the seams in different directions). This is your quilt top.

- Press these joining seams open.

- Press the quilt top on the right side, ensuring that you don’t dislodge any of the seam allowances on the wrong side.

- Press and lay the backing sheet on the floor.

- Cut the batting or interlining to size, joining by butting the edges together and using a loose hand stitch. Lay this on top of the backing.

- Lay the quilt top, face up, on top.

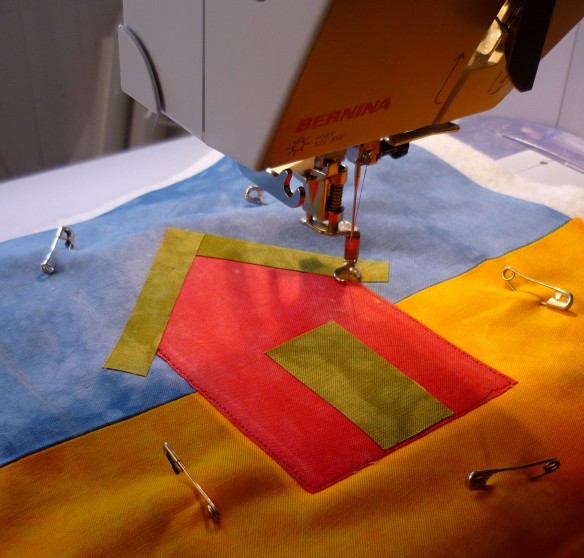

- I quilted my piece, using a walking foot, 1/2″ in from each long vertical and horizontal seam but any quilting you choose will be fine. Or, if you don’t want the struggle of getting the rolled up quilt through your machine, use buttons!

- For the binding cut 4 x 4″ strips, 80″ long, from the green striped fabric. To avoid the risk of the binding looking a bit skewed, if it wasn’t quite square, I cut the binding with the stripes going across the strip instead of down.

- Fold each strip in half widthways and press.

- Pin one strip to one of the outer edges of the quilt, lining the raw edges up with the raw edges of the squares. Stitch 1/2″ from the edge. Trim all the excess backing and batting off flush with the raw edges of the squares.

- Pin and stitch a second strip to the opposite edge.

- Now flip the binding over and press. Fold under so it touches the stitching you joined it with. Press and pin.

- Attach the other two strips, leaving a 2″ overhang at each end. Flip over the binding and press. Turn in the overhang then fold under, press and pin.

- I machined round my binding, 1/8″ from where it joins the quilt, but it was tough stitching over the corners. Hand stitching will give it a softer finish.

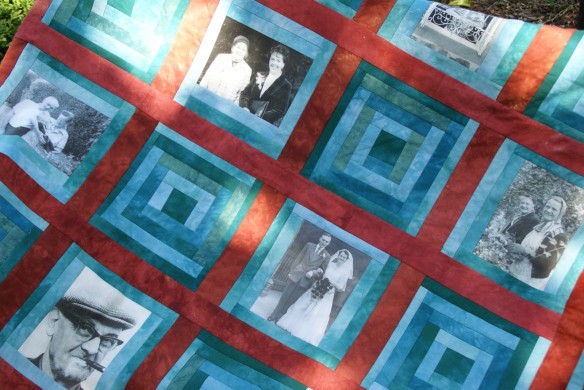

I really enjoyed making this quilt. There’s a lot of sheets left over and next time I might add some old photos printed onto fabric.

I really enjoyed making this quilt. There’s a lot of sheets left over and next time I might add some old photos printed onto fabric.